Location -> News

News

industrial dispensing metering pumps

Email:sales01@cxflowmeter.com

whatsapp:008618049841995

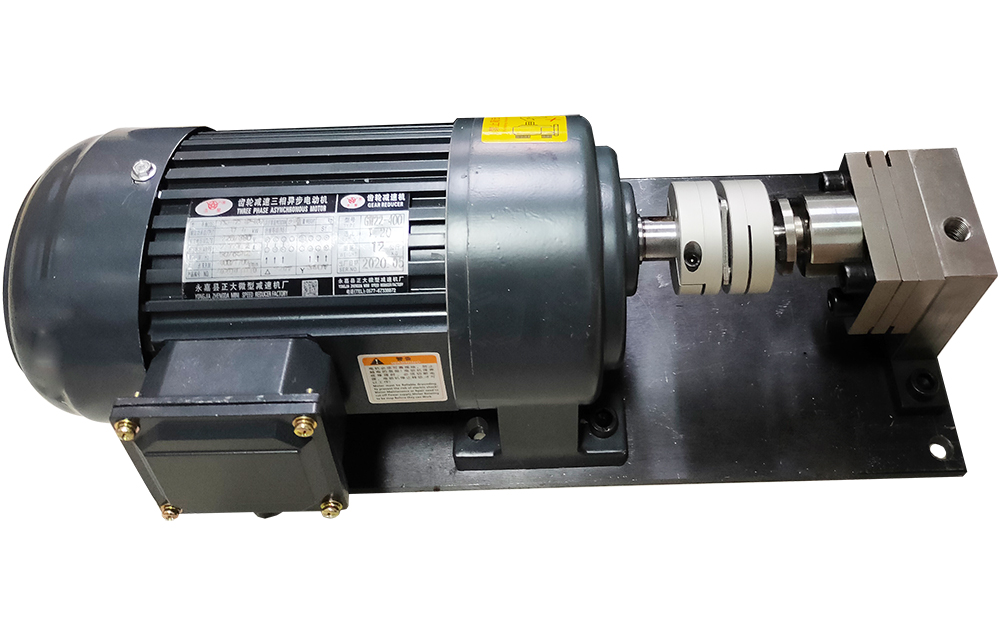

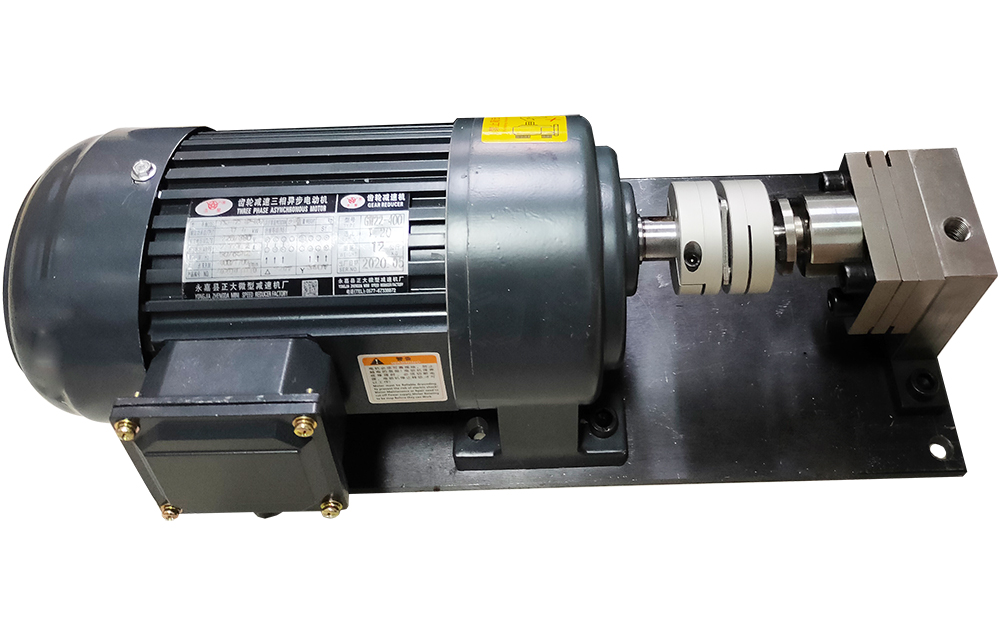

What are the industrial dispensing metering pumps?

There are many types of industrial dispensing metering pumps, and these pumps can meet the needs of precise quantitative delivery of glue in terms of design and function. So what are the specific types?

Working principle: The working principle of the gear metering pump is similar to that of an ordinary hydraulic pump, mainly including several stages such as suction, discharge, and control. The motor drives the reducer and gear pump to operate, and sucks the glue from the glue barrel into the pump cavity. When the pressure in the pump cavity reaches a certain value, the controller will instruct the gear pump to stop sucking liquid and increase the output pressure to make the glue flow out along the high-pressure pipeline. The controller can set appropriate parameters to control the flow rate and flow rate of the dispensing pump.

Features and advantages:

Simple structure and easy maintenance.

Accurate measurement, can meet the needs of high-precision dispensing.

Suitable for glue of various viscosities.

Widely used in dispensing operations in electronics, semiconductors, automobiles and other industries.

2. Screw metering pump

Working principle: The screw metering pump sucks the glue from the glue inlet through the rotation of the screw, and gradually compresses it in the gap between the screw and the pump body, and finally discharges it from the glue outlet. The speed of the screw and the structure of the pump body determine the flow rate and accuracy of the glue.

Features and advantages:

Stable delivery and wide adjustable flow range.

Suitable for high-viscosity and easy-to-crystallize glue.

Accurate metering, suitable for occasions where the amount of glue needs to be precisely controlled.

Widely used in chemical, food, pharmaceutical and other fields.

3. Plunger metering pump

Working principle: The plunger metering pump sucks and discharges glue through the reciprocating motion of the plunger in the pump cylinder. When the plunger moves backward, the pressure in the pump cylinder decreases and the glue is sucked in; when the plunger moves forward, the pressure in the pump cylinder increases and the glue is discharged. By controlling the movement speed and stroke of the plunger, the flow rate of the glue can be accurately controlled.

Features and advantages:

High metering accuracy, suitable for occasions requiring extremely high precision control.

Compact structure and small footprint.

Suitable for conveying high-viscosity, particle-containing glue.

It has important applications in the fields of petroleum, chemical, pharmaceutical, etc.

4. Other types of metering pumps

In addition to the common metering pumps mentioned above, diaphragm metering pumps and peristaltic pumps are also commonly used in the field of industrial dispensing. These pumps have their own characteristics. For example, diaphragm metering pumps have the advantages of corrosion resistance and no leakage; peristaltic pumps are suitable for conveying volatile and corrosive glue.

For specific selection and quotation issues, please consult CIXIFM winny:

Email:sales01@cxflowmeter.com

whatsapp:008618049841995

Last:Turbine flow meters working pri.. Next:water level sensors types and c..